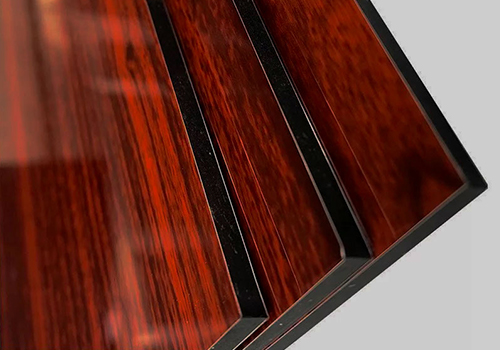

Wooden Aluminium Composite Panel

ALCLOUD ® Wooden Aluminium Composite Panel

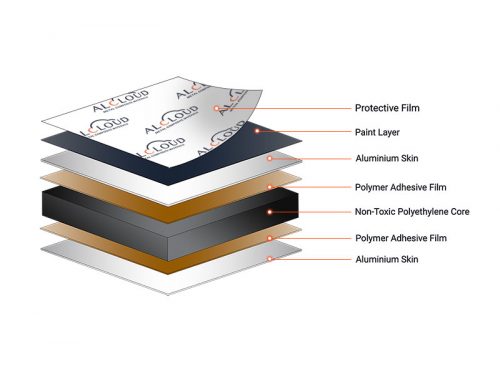

Unlike natural wood, which is eaten by termites & fungus, swelled by moisture, and gets dirty with time, Aluminium Wood Panel does not have any of these faults because they are made of two thin aluminum sheets laminated on a Polyethylene core which makes them super-flat, lightweight, moisture resistant, and highly durable.

ALCLOUD ® Aluminium Wood Panel Manufactured in China

ALCLOUD ® Aluminium Wood Panel Applicable For Your Projects

Applications

Why ALCLOUD ® Wooden Aluminium Composite Panels

Let's Start Designing Your Aluminum Composite Panel.

Capabilities Overview

- 3mm

- 4mm

- 5mm

- 6mm

- PE

- PVDF

- Non-toxicity LDPE

- B1 Fire-resistant

- A2 Fire-resistant

Sizes

Packaging

Testing

Surface Properties

Paint Thickness (micron) | 20 |

Pencil Hardness | ≥ HB |

Gloss deviation | ≤ 10 |

Toughness of Coating | ≤ 3T |

Temperature Resistance | -50°C to + 90°C |

Impact Strength (kg cm2) | 42 |

Boiling Water Resistance | Boiling for 2 hours without change |

Acid Resistance | Immersed surface in 2% HC1 for 24hrs without change |

Alkali Resistance | Immersed surface in 2% NaOH for 24hrs without change |

Oil Resistance | Immersed surface in 20# engine oil for 24hrs without change |

Cleaning Resistance | > 1000 times without change |

Peel Strength | > 5 Newton/mm |

Product Properties

Weight (Kg/m2) | 3.55 |

Sound Absorption NRC | 0.05 |

Sound Attenuation Rw db | 24 |

Water Absorption % by volume | 0.01 |

Thermal Performance R Values | 0.0057 |

Core Composition | Polyethylene |

Core material calorific value of combustion | ≤ 12 |

Flammability class for panels | B1 |

Tolerances

Thickness (mm) | -0.2 / + 0.2 |

Width (mm) | ± 2 |

Length (mm) | ± 3 |

Diagonal (mm) | ≤ 5 |

Aluminum Thickness (mm) | ± 0.02 |

- PVDF finish over 15 Years

- PE finish over 5 Years

- T/T

- LC at sight

- CIF

- FOB

- CFR

- EXW

FIND OUT ALCLOUD® MORE /

Exploring More with ALCLOUD ® Wooden Aluminium Panel

Your Building Project Using Wooden Aluminium Composite Panel.

Residential Places

Unlike in the old days when print was the only option, now you can cover every inch of walls of houses, flats, bungalows, etc., with Wooden ACPs to make your place beautiful and look natural.Education Buildings

A beautiful & neat environment makes students happy, which in return helps them focus on their studies. So, wooden ACPs are also very commonly used in schools, colleges, libraries, universities, and so on.Public Places

In bustling areas like bus stations, subways, airports, etc., it is best to use ACPs because they can be scratch-proof, heat-resistant & sturdy, making them last decades while paint or natural wood will be damaged in just a few months.Commercial Buildings

In Places like banks, hospitals, hotels, offices, etc., where attracting customers is necessary, you can use Wooden ACPs. These panels will make your building stand out from the rest of the market and get everyone towards your place, which will get you profits.Benefits of Using Wood Aluminium Panel?

Sound-Proof

As we discussed earlier, ACM Panels have three layers, while the middle core layer is polyethylene which also provides sound insulation and keeps the road or outside sound from coming inside, making the environment quiet & calming.

Outside Use

Wood Aluminium Composite Panels have a protective covering that prevents rusting, fading, cracking, bending, or any damage under harsh environmental conditions like sunlight, rain, heavy winds, etc. That's why Wooden ACP Sheets can also be used in the outside environment.

Easy Cleaning

Wood ACM Panels have a flat & non-porous coated surface which makes the dust, fluid, food, hand prints, etc., tough to get into the panel and leave a permanent mark. Wooden Aluminium panels are practically 99% stain-resistant; when dirty, all you need to do is wipe them with a cloth, and they will shine like a mirror.

Long-Life

Wood Finish ACM Panel may look thin & weak, but aluminium can not rust like iron, and it does not crack due to its flexibility, making it almost indestructible. When you buy Wooden Aluminium Sheets, you can expect to get 10 ~ 20 years of lifespan in public areas & more than 20 years in homes.

Safe

One of the main concerns while cladding is how the material will react in emergencies like a fire, earthquakes, etc. Wood & PVC panels can easily catch fire and worsen the problem, while Wooden Aluminium Panels do not catch fire; they only melt around 650° C without releasing harmful gases.

Shape Flexibility

Wooden ACP Sheets being flexible, can be converted into any design, which was only a dream a few years ago. Square, Triangular, Tube, Open Cell Grid, Hexagonal, Bend, and any other shape can be made to fit your building's unique structure.

Budget-Friendly

The best thing to see here is that aluminium is far cheaper than wood yet far more robust than wood. Plus, ACM Panel is easy to install and clean.

Overall, Wood Aluminium Panel is the best choice over wood, even in terms of costs.