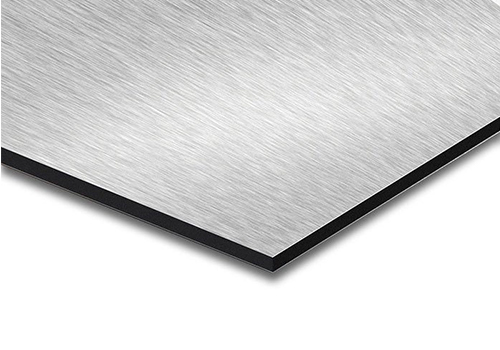

Brushed Aluminium Composite Panel

ALCLOUD ® Brushed Aluminium Composite Panels

ALCLOUD ® Brushed ACM Panel Manufactured in China

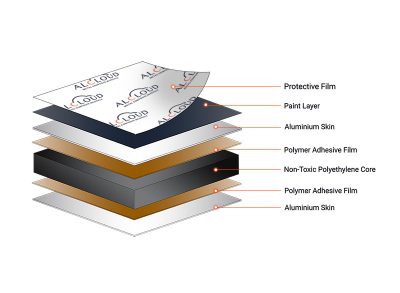

Brushed ACM Panels are manufactured by repeatedly scraping aluminium panels with sandpaper. The process is divided into three parts: de-estering, sanding, and washing.

ALCLOUD ® Brushed ACM Applicable For Your Projects

Brushed ACM Panels offer all the versatility of our classic polyethylene core panels, providing superior flatness, vibration damping, durability, and ease of maintenance to realize your architectural vision beautifully.

Applications

Why ALCLOUD ® Aluminium Composite Panels

Let's Start Designing Your Aluminum Composite Panel.

Capabilities Overview

- 3mm

- 4mm

- 5mm

- 6mm

- PE

- PVDF

- Non-toxicity LDPE

- B1 Fire-resistant

- A2 Fire-resistant

Sizes

Packaging

Testing

Surface Properties

Paint Thickness (micron) | 20 |

Pencil Hardness | ≥ HB |

Gloss deviation | ≤ 10 |

Toughness of Coating | ≤ 3T |

Temperature Resistance | -50°C to + 90°C |

Impact Strength (kg cm2) | 42 |

Boiling Water Resistance | Boiling for 2 hours without change |

Acid Resistance | Immersed surface in 2% HC1 for 24hrs without change |

Alkali Resistance | Immersed surface in 2% NaOH for 24hrs without change |

Oil Resistance | Immersed surface in 20# engine oil for 24hrs without change |

Cleaning Resistance | > 1000 times without change |

Peel Strength | > 5 Newton/mm |

Product Properties

Weight (Kg/m2) | 3.55 |

Sound Absorption NRC | 0.05 |

Sound Attenuation Rw db | 24 |

Water Absorption % by volume | 0.01 |

Thermal Performance R Values | 0.0057 |

Core Composition | Polyethylene |

Core material calorific value of combustion | ≤ 12 |

Flammability class for panels | B1 |

Tolerances

Thickness (mm) | -0.2 / + 0.2 |

Width (mm) | ± 2 |

Length (mm) | ± 3 |

Diagonal (mm) | ≤ 5 |

Aluminum Thickness (mm) | ± 0.02 |

- PVDF finish over 15 Years

- PE finish over 5 Years

- T/T

- LC at sight

- CIF

- FOB

- CFR

- EXW

FIND OUT ALCLOUD® MORE /

Exploring More with ALCLOUD ® Brushed Panels

The Difference between a Brushed ACM Sheets Vs. Brushed Metal Sheets?

Brushed ACPs | Brushed Metal Sheets | |

Structure | Two thin Aluminum layers Laminated on PE core and a Brushed effect finish is done | Mode of pure sheets of Stainless Steel & other metals |

Surface Finish Feel&Quality | ||

Weight | Very light as compared to pure metal sheets | Very Heavy |

Ease of Moving & Fabrication | Lightweight easy to transport,cut,and mount | Hefty weight and complex,not easy to move & fabricate |

Shapes Variety | Flexible,can be bent to make many shapes | Flexible but rigid offers fewer shapes variety |

Price | Very Low | Very High |

What is the Difference Between a Fire-Proof Core Vs. a Normal Core?

Both Cores are Normal & Fire-proof and have heat resistance properties.In case of fire,

The standard cores, made of LDPE / HDPE, will resist combustion, but if the temperature rises above legal limits, they will catch fire.In contrast,

Fire-proof cores, made of special mineral ores, will resist fire to a higher degree. Fire-proof cores also come in many grades; the higher ones will never get combustible no matter what.

How do we get started with the Aluminium Composite Materials you need?

Step 1: Tell Us What You Want

In this step, fill out the following chart and send your inquiry. " Your Requirements Aluminum Skin Thickness Size ( Length x Width x Height ) Normal Core or Fire-Proof Core Surface Finish Your Desired Color ( Picture, Color code if possible ) "Step 2: Sample Making & Order Confirmation

We will make a sample as per your demands of the exact size, color, shape, and other features. Send the sample to you within 7 days. Finally, we will proceed to bulk order. when you pass the sample.* All you need to do is pay a 30% advance and we will send daily pictures & videos of your order-making process.*

Step 3: Receive your Order at your DoorStep

We are free to accept Third-party inspection after full order production. To make sure you’ll have complete peace of mind about quality before full payment & shipping. We will pack and ship your order at the destination port of your choice, or you can also choose our Full-package shipping service, in which we will deliver the order to your doorstep.