Aluminium Honeycomb Panel

What is the Aluminium Honeycomb Panel?

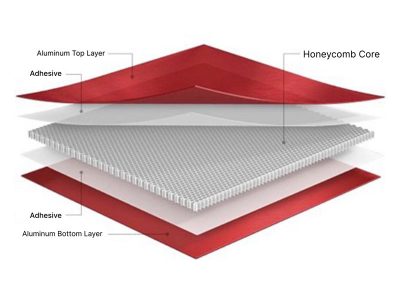

Aluminium Honeycomb Panels are the future of every industry, from Aerospace to making Trashcans, because a Honeycomb panel has less weight but more tensile & compression strength than a solid panel of the same height & material.

ALCLOUD® Aluminium Honeycomb Panel Manufactured in China

ALCLOUD® aluminum honeycomb panels are generally made of 3003, 5005/5052, and other aluminum alloys, and 1100 panels with low alloy composition are rarely used. The decorative surface is sprayed or rolled, and the coating is polyester or fluorocarbon paint.

The Aluminum Honeycomb design works like an I-Beam Structure, creating very High-Values of Shear Strength.

ALCLOUD® Aluminium Honeycomb Panel Applicable For Your Markets

Applications

Why ALCLOUD® Aluminium Honeycomb Panel

Freeing Your Architectural Design Like Clouds.

Let's Start Designing Your Aluminum Composite Panel.

Capabilities Overview

Capabilities

- 8mm

- 8.6mm

- 9mm

- 10mm

- 10.6mm

- 11mm

- 23mm

- 23.6mm

- 24mm

- More …

Sizes

- 1220 mm

- 1250mm

- 1500 mm

- 2000 mm

- 2100 mm

- More …

More Custom Sizes

Honeycomb Core Properties

- 3003

- 3105

- 5005

- ¼ inch ( 6.3mm )

- ⅜ inch ( 9.5mm )

- ½ inch ( 12.7mm )

- ¾ inch ( 19.1 mm )

Technical Specifications

- Polyethylene ( PE )

- Polyvinylidene difluoride ( PVDF)

- Fluoroethylene vinyl ether ( FEVE )

- AA3003

- AA3105

- AA5005

- AA5052

- PVDF finish over 20 Years

- FEVE finish over 15 Years

- PE finish over 5 Years

- T/T

- LC at sight

- CIF

- FOB

- CFR

- EXW

FIND OUT ALCLOUD® MORE /

Exploring More on What You Need to Know about Aluminium Honeycomb Panel

Why Choose ALCLOUD as Your Metal Honeycomb Panels Supplier?

We are not unique; we are just one of the thousands of Metal Honeycomb Panels manufacturers worldwide. So, why should you choose us; it is simple;

We are not a market giant, but we are also not a small company. We are one of the most famous companies in China in this niche. But now we want to become world-famous, and we need to make clients in every country. So,

Your order will mean a lot to us, and we will work day and night to give you the best quality and lowest prices to make you our long-term client. Plus,

“We do not believe in Blind Trust, we offer free Third-Part Inspection of the agency of your choice before every shipment, and we have up to 20 years of warranty on our panels to back you up in case of any fault.”

Types of Aluminum Honeycomb Panel

Elevators Use Panels

Unlike Solid Panels, Honeycomb Aluminum Panels have less weight, making the lifts, cabins, cable cars, etc., made with them to climb up or down easier & fastly; which will save a lot of time and energy.Marine Corrosion-Proof Panels

To achieve speed & efficiency, ships are constructed from Lightweight materials, most commonly with Aluminum Honeycomb Panels. As Aluminum is very Corrosion-resistant, so it is ideal for the sea. You can use these as Decking, Partitions, Gang Planks, ceilings, etc.Interior Furniture Panels

We make standard, edged & special shape panels. Our Honey Comb Panels are famous for making furniture like Office Tables, Dressing Cabinet Partitions, Coffee Tables, Whole Storage Cabinets, Basin Stands, etc.

Signage & Display Panels

Made to withstand Harsh Winds, our Signage Honeycomb Panels are the best for the Outside Environment. With an extra smooth surface finish, you can easily print High-Resolution advertisements or logos on it. You can also use these panels for interior Art & Crafts displays.Ballistic Panels

Due to their impact absorption & debris holding abilities, Aluminum Honey Comb Panels are used in the Military and public sectors where there are risks of explosions, gunfire, and other ballistic conditions.Panels to Make Products

Honeycomb panels are used to make many Consumer Level Products like Flight Boxes, Refrigeration Units, headphones, speakers, etc. It is because they have a very high strength-to-weight ratio, ideal for constructing budget-friendly products by using less material but getting the same strength as solids.Building Use Panels

Nowadays, everybody is racing for bigger & bigger buildings. But holding all that weight on a single base needs lightweight materials such as Honey Comb Aluminum Panels to make Doors, Ceilings, Floors, Facades, Walls, etc.Transportation Sector Panels

As fuel pricing is rising each day, Honeycomb panels are becoming more & more famous for making locomotion vehicles like trains, buses, cars, etc. It is because their lightweight help saves costs and decrease CO2 emission, which reduces global warming.Controlled Room Panels

Aluminum Honey Comb Panels do not emit gases, are highly chemical & moisture resistant, vibration dampening, sound-proof, sturdy, and fire-retardant; making them ideal to made Clean or Controlled rooms for patients, VIP rooms, Laboratories, and so on.Installation Process of Aluminum Honeycomb Panel for Wall System

Lug type

The lugs are separated from the honeycomb board, and the lugs are separately processed and connected to the adhesive joints of the honeycomb board, with the suitable width of the adhesive joints being ≥12mm. This installation method makes processing simple and installation convenient.Flap type

When processing the aluminum honeycomb panel that is processing the flap installation, the structure only needs to connect with the keel, and the glue seam comfortably can be suitable for a glue seam width of ≥ 10mm. This method is easy to install, but the processing is slightly complex and unsuitable for modeling curtain wall panels.Buckle type

The buckle is a specific profile and easy to install, but this method requires high precision for plate processing and is not recommended for plates with a length greater than 3000mm.

Aluminium Honeycomb Panel Vs. Aluminium Veneer

The honeycomb aluminum panel can be up to 1500mm×4500mm; the whole panel is a composite material, and the internal aluminum honeycomb guarantees the board itself to bear its weight so that the board itself does not need to add any reinforcement.

An ordinary aluminum veneer in width greater than 1m or length greater than 2m must be added behind the board stiffening ribs. The stiffening ribs need to be welded on the back of the board because the thermal expansion coefficient of the stiffening ribs and the board itself are not the same. After several times of hot and cold changes, the front of the board will appear uneven phenomenon. This phenomenon usually occurs half to one year after the project is completed.

The aluminum veneer is a single-layer product with relatively simple processing and strong modeling ability but poor precision; the honeycomb panel is a composite product with weaker processing speed and capacity but guaranteed precision.

The honeycomb aluminum panel adopted is the buckle cover system, and there are two systems of exposed glue seam and hidden glue seam available. The system fully considers the influence of thermal expansion and contraction on the board surface itself, and the board surface can be freely expanded in all four directions, effectively avoiding the effect of temperature stress on the flatness of the board surface.

Ordinary single-layer aluminum panels only have an adhesive seam exposed system. The installation is fixed on the keel with the installation code, which has no suitable space to release the temperature stress and causes the board surface to warp easily.

Honeycomb panel is a composite panel with the advantages of light quality, high strength, good flatness, large board surface, easy installation, easy maintenance, good environmental protection, reusable and excellent resistance to thermal expansion and contraction.

The aluminum veneer is an ordinary non-composite plate. Compared with a honeycomb plate, it does not have the above advantages, but the cost of a 3MM thick aluminum veneer is generally 15 ~ 20% lower than a 25MM honeycomb plate. Because of the self-weight and molding reasons, the building uses less used 4MM thick aluminum veneer, and this thickness of the aluminum veneer cost difference from the honeycomb panel products is only about 5%.

Warranty on Our Aluminium Honeycomb Panel?

We at ALCLOUD manufactured our Aluminum Honeycomb Panels from the finest materials in our state of art factories. Unlike Others, we do not forget our customers after selling the panels; we have an Easy After-Sale Service policy. Although,

Our Panels will last for decades without any fault for any faulty pieces we give;

“ 10 ~ 20 Years of Warranty, depending on the Quality.”

“We are here to make the World a Better Place, and you can contact us anytime on our 24/7 Helpline Service.”